Give us a call on

-

-

You may send an email

info@hyalineenviro.com

Give us a call on

You may send an email

Reverse osmosis is the most e cient method of removing 90% to 99% of all contaminants. The pore structure of RO membranes is much tighter than UF membranes. membranes are capable of rejecting practically all particles, bacteria and organics >300 Daltons molecular weight. Natural osmosis occurs when solutions with two different concentrations are separated by a semipermeable membrane. Hyaline Enviro Design, the plants based on the raw water parameters and the standard models available from 200Lph onwards. As per the customer requirement, application and capacity, our systems exceed the standards with outstanding performance and hence we are the most preferred vendor in this filed. We are specialized in fully automated plants.

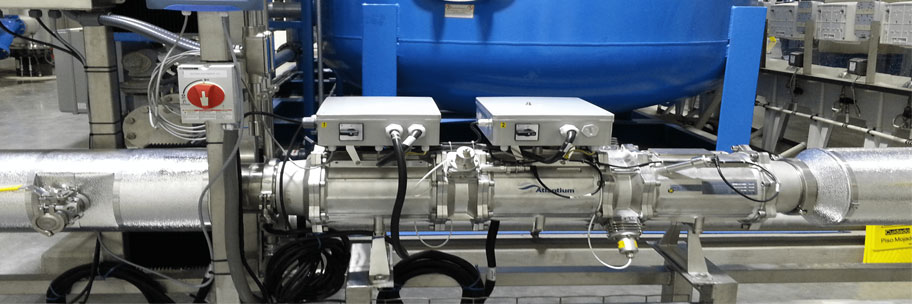

Electrocoagulation (EC) is a water treatment process whereby an electric f ield is applied across plates to remove various contaminants from water. An Electrocoagulation water treatment system represents a major advancement i n wastewater treatment. It is revolutionary Electrical-Machanicla technology for effectively treating complex waste streams economically on-site. Current is applied to the electrolytic cell plates causing trace amounts of the plate material to be dissolved into the water. The action is similar to adding separation chemicals (polymers) to a chemical treatment system but much less expensive

Water Treatment using UV system does not involve any chemicals. It is Physical Treatment, so it does not alter the water chemistry. UV adds nothing to the water such as undesirable colour, odour, taste or f lavour. UV or Ultra Violet rays are in the electromagnetic spectrum and between visible light and X-rays. In order to kill microorganism, the UV rays must actually strike cell. UV rays penetrate the outer cell membrane, passes through the cell body and disrupt its DNA preventing reproduction. Hyaline Enviro's “UV systems” are customized for customer to customer. As the micro organisms' nature changes with the atmospheric conditions, Our team study the nature of the water and Design the Systems ranging from 50Lph to 2,00,000 Lph.

Hyaline Enviro has unique technical specialization to develop DM plant's output water parameter Conductivity l ess than 0.1 mS/cm We Design, Engineering & Erect highly rated DM plants, which are better used for various industries such as Power, Pharma, Chemical industries, Paper& Pulp.. Demineralized water also known as Deionized water; Demineralised Water System finds wide application in the field of steam, power, process, and cooling. This works based on the principle of when hard water is passed through ion exchange resins, cations get exchanged with hydrogen ions in first stage and anions exchanged with hydroxyl ions in second stage.

Ultra Filtration acts as a Pre-Treatment before Reverse Osmosis, which increases RO availability factor Ultra f iltration is a separation process using membranes with pore sizes in the range of 0.1 to 0.001 micron. Typically, ultra f iltration removes high molecular weight substances, colloidal materials, and organic and inorganic polymeric molecules, but Low molecular-weight organics and ions such as sodium, calcium, magnesium chloride, and sulphate are not removed. Due to the negligible differential osmotic pressure across the membrane surface, only high-molecular weight species are removed. Hyaline Enviro's Ultrafiltration systems are extremely effective for treating heavy surface water. Ultra-filtration treated water can be sent for reverse osmosis and recycled or further taken for portable application. Hyaline Enviro Experts in Designing Engineering, Erection and commissioning of automated ultra filtration plants; Our Ultra Filtration systems are free from clogging and hence work effectively.

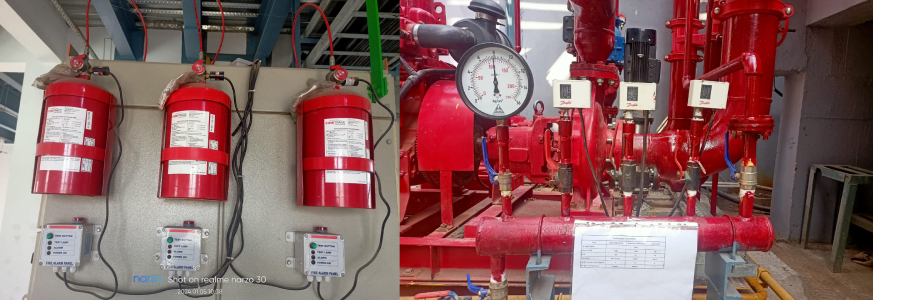

Hyaline Enviro is pioneers in Designing and Engineering of Chlorination Systems and Accessories, used in Drinking Water, Cooling Water, Waste Water Treatment and other specialized applications. Hyaline Enviro has a state-of-art knowledge and highly experienced professional team. We Design, Engineering, Erection & Commissioning of Chlorination Systems & Accessories on Turn - key Basis. Gas Chlorinators are used in Fertilizer plants, Oil Refineries, Petrochemical Industries, Thermal Power Plants, Steel manufacturing plants, Pharma Industries, Pesticide manufacturing plants, Food & Beverage Industries, Paper and Pulp Industries, Sugar Plants for combating slime and algae.

Nano Filtration is a pressure driven separation process. Selective separation l ayer is formed by organic semi permeable membrane for the Nano Filtration process.The “Pressure” difference between the 'Feed' and ' Filtrate' at the separation side of membrane is the key Parameter for the Nano Filtration. Nanofiltration (NF) is a rapidly advancing membrane separation technique for water and wastewater treatment. NF can be defined as a pressure driven process wherein the pore size of the membrane (0.5 - 1 nm) as well as the trans membrane pressure (5 - 21 atm) lies between reverse osmosis and ultra filtration. NF membranes allow partial permeation of monovalent salts such as sodium chloride while rejecting bivalent salts and hardness to a greater extent from aqueous solutions. NF can remove lower TDS and hardness reduce colour and odour, and remove heavy metal ions from ground water. Nan filtration is used as an independent system to treat water, or as a pretreatment to reverse osmosis, thereby, reducing the load on RO

Hyaline Enviro has extensive experience in developing Water Softeners to remove scaling. Water Softeners are specific ion exchange equipment, which is used to soften the water, by removing the minerals that cause the water to be hard. Minerals like calcium and magnesium present in the water in their carbonates and bi carbonates form and makes the water hard which creates scaling when it is used in industrial as well as in other domestic applications. Water softening plant uses Ion Exchange process which relies on the replacement of the Calcium and Magnesium ions present in the water by an equivalent number of Sodium ions. This eliminates the unwanted characteristics of hard water because the sodium salts never forms scale in any of the machinery parts. The resins get charged by sodium chloride solution (common salt) which is the cost effective and easiest maintenance process. Hyaline Enviro offers customized water softening systems in various sizes for Residential, Restaurants, Commercial and Various industrial applications.

We do complete Pre treatment plant for various industries such as Pharma, Chemical, Textile, Power, Sugar, Cement, Paper & Pulp, and Food; In pre-treatment, River water is pumped to the Water Purification Plant and distributed from the Plant through several large pipelines. River water contains large amounts of suspended solids. Treatment under go various stages of processing as followed, STAGE 1 - Coagulation | Stage 2 - Flocculation | Stage 3 - Sedimentation | Stage 4 - Disinfection Stage 5 - pH Adjustment | Stage 6 - Filtration

Ozone is the strongest and most effective natural algaecide, bactericide, disinfectant, fungicide, germicide, and sanitizer and anti viral agent. Activated oxygen not only destroys all pathogenic disease causing microbes, it also destroys fungal pathogens, cysts, parasites, protozoa and some yeasts too. Ozone is a triatomic molecule (O3) consisting of three oxygen atoms. It is an allotrope of oxygen that is much less stable than the diatomic (O2, regular oxygen). It is a gas made from air and high voltage.The injection of ozone into water produces tiny ozone bubbles, which saturate the water.

Government has been emphasizing the recycle of waste water and sewage from residential colonies & a partments, Hotels, Restaurants, Hospitals, IT parks and strictly targeted these communities to follow pollution norms. Hyaline Enviro has developed innovative, economical and easy to operate STP Systems. Sewage Treatment Plant.

Industrialization has been increasing the ground water contamination. Environmentalists' concerns and peopleagitation made many companies which are releasing waste liquid hazardous has to follow states & central government's pollution rules strictly. Hyaline Enviro Engineers' team has specialization to analyze the complex e uent samples for different euent Parameters as per the nature and compositions to carry out the treat-ability studies by using different methods, checking techno commercial Feasibility and then to prepare various designs for treatment processes accordingly to suit the purpose and need of the customer. Our ETP systems are compact, customized, portable, requires less space and energy e cient. The principle of operation ETP, is Physico Chemical treatment followed by Polishing Treatments like –Sand Filtration, Activated Charcoal treatment (Adsorption), Ozonisation (Chemical Oxidation), Ultra Filtration (UF), Reverse Osmosis (RO) and then followed by evaporation based on requirement. We Design, Engineering, Erection and Commissioning of Customized Euent Treatment Plants (ETP) on Turnkey basis We also undertake “up-gradation”, “modifications” in the existing ETP systems to achieve desired limiting standards laid down by the Pollution Control Board (PCB).

There has been a growing demand for small and medium-sized oxygen equipment with rapid development of the national economy in recent years. Beijing Peking University Pioneer Technology Co., Ltd. (hereinafter referred to as PIONEER), seizing this market opportunity with its advanced technology and engineering experience of more than 100 sets of oxygen equipment, has produced the customized the new skid-mounted PSA oxygen equipment through its continuous development and innovation. The PSA-O2 generator meets a wide range of requirements for users in need of small and medium-sized oxygen equipment. It has remarkable advantages on its stability, simplicity, efficiency and energy saving.